Introduction

Fire safety is paramount in any industrial setting, but it’s especially critical in crackers manufacturing units where the presence of combustible materials and ignition sources can pose significant risks. In this blog post, we’ll explore essential fire safety measures that can help mitigate these risks and ensure the safety of your employees and facility.

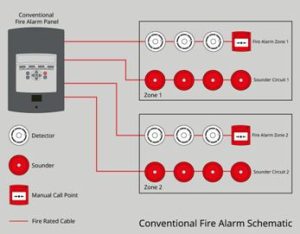

Fire Detection Systems: Early detection of fires is crucial for prompt response and containment. Install smoke detectors, heat detectors, or fire alarms throughout your facility to provide early warning in case of fire. Automatic fire detection systems can help alert employees and initiate emergency response procedures swiftly, minimizing potential damage.

Appropriate Fire Extinguishers: Selecting the right type of fire extinguishers is vital for effectively combating different types of fires. In a crackers manufacturing unit, fire extinguishers suitable for Class B (flammable liquids), Class C (electrical), and Class A (ordinary combustibles) fires are essential. Consider using ABC, dry chemical extinguishers, carbon dioxide (CO2) extinguishers, or clean agent extinguishers, strategically placed in accessible locations throughout the facility.

- Proper Storage of Flammable Materials: Flammable materials used in the manufacturing process, such as chemicals and solvents, should be stored in designated areas that are well-ventilated and separated from ignition sources. Implement proper labeling and storage procedures to minimize the risk of accidental ignition and ensure compliance with safety regulations.

- Electrical Safety Measures: Electrical hazards are a common cause of fires in industrial settings. Implement proper electrical safety measures, including regular inspection and maintenance of electrical equipment, avoidance of overloaded circuits, and use of explosion-proof electrical fittings where necessary. Training employees on electrical safety protocols is also crucial to prevent accidents. In the case of large industries Electrical Panel Suppression system is recommended.

- Hot Work Permit System: Hot work activities like welding and cutting pose additional fire hazards. Implement a hot work permit system to ensure that proper precautions are taken before undertaking such activities. This includes conducting a risk assessment, implementing fire prevention measures, and obtaining authorization from designated personnel.

- Fire Hydrant and Sprinkler Systems: It’s a requirement to install sprinkler systems or water mist systems in areas prone to fire hazards. These systems play a crucial role in swiftly suppressing fires, thereby containing their escalation and bolstering safety measures for both your facility and personnel.

- Emergency Preparedness and Training: Prepare and regularly review emergency response plans with all employees, including evacuation procedures, assembly points, and roles and responsibilities during emergencies. Conduct fire drills to practice evacuation procedures and ensure that employees are familiar with emergency protocols. Providing fire safety training to employees can help raise awareness and promote a culture of safety in the workplace.

Conclusion: Guaranteeing fire safety in your crackers manufacturing facility isn’t just a legal obligation but also critical for safeguarding your employees, property, and business continuity. By adhering to the fire safety guidelines highlighted in this blog post and remaining vigilant, you can mitigate the likelihood of fires and establish a safer workspace for all. In smaller production units, it’s imperative to have at least one fire extinguisher, while larger manufacturing units necessitate a comprehensive hydrant and sprinkler system.

#SafeCrackers

#FireworksSafety

#PyrotechnicSafety

#FireSafeFestivities

#ResponsiblePyrotechnics

#IgniteResponsibly

#PyroSafetyFirst

#CelebrateSafely

#SparkSafe

#PyroPrecautions

#srsfiresafety

#SRSEnterprises

#firesafety